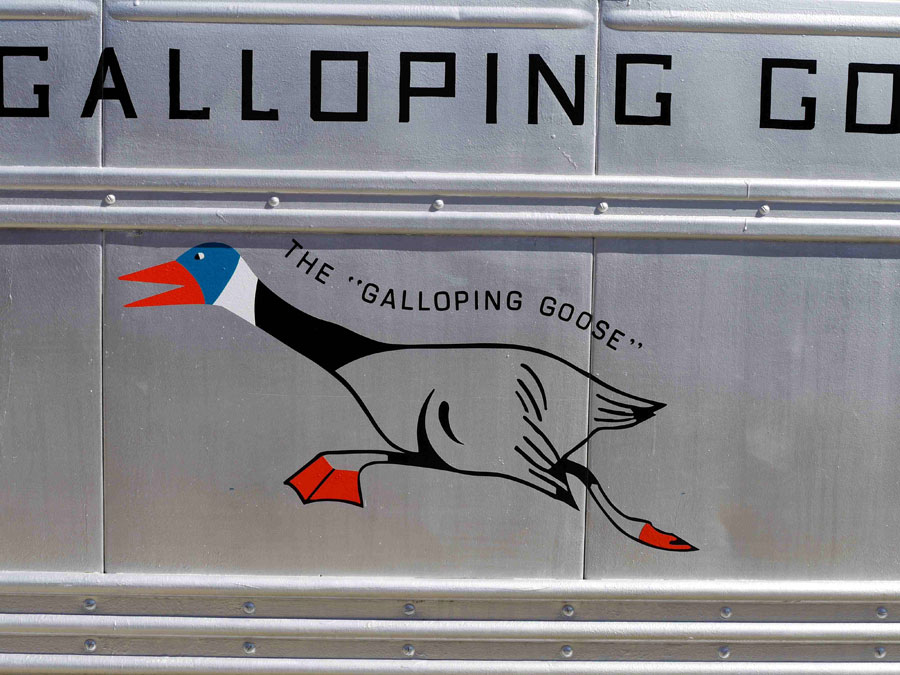

RGS Goose 4 Comes to Ridgway for

Restoration

|

|

The Ridgway Railroad Museum has a signed formal

agreement with the Telluride Volunteer Fire Dept (TVFD) to

restore Galloping Goose No. 4 to operating condition. The TVFD

deserves a big thank you for keeping No. 4 in condition such

that it is still possible to do this restoration after 55

years.

No. 4 is the only Goose that has not been restored or

otherwise modified. It is therefore the best information we

have about what the Geese were like in 1951 when the RGS shut

down operation.

We will did the work and the TVFD paid for the

materials. The move to Ridgway occured in May of 2008. The

first phases was to research for photos from summer of 1950

for our prototype, document existing condition with photos and

drawings, determine parts that will have to be acquired and

materials that will be replaced (all the wood), and carefully

begin disassembly of the rear box.

The Galloping Goose Historical Society of Dolores has

shared all of their expertise obtained in their restoration of

Goose No. 5. They have been very helpful in providing

information on what and how they did their work.

We have completely rebuilt the frieght/passenger box

using the same construction techniques as used in the

original. The engine and transmission were been rebuilt in

Telluride. The power truck and the trailing truck have been

completely refurbished and reinstalled. The original Denver

Tramway seats have been re-canned and restored.

The restoration was completed in Spring 2012. The photo below

shows restored Goose No. 4 running on the Cumbres and Toltec

Scenic Railroad.

YOU CAN FOLLOW THE MOVE FROM

TELLURIDE TO RIDGWAY AND THE RESTORATION PROCESS BY

SCROLLING THROUGH THE FOLLOWING PHOTOS.

|

1) May 15, 2008 in Telluride. We oiled all sixteen axles and then

pulled the goose back about one foot and all 16 axles turned!

2) The following series of photos show the loading

process in Telluride on May 29, 2008

3) Goose #4 pauses on Dallas Divide for the first

time in 56 years.

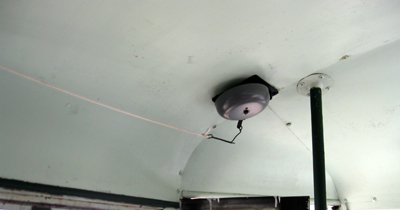

4) Arrival in Ridgway.

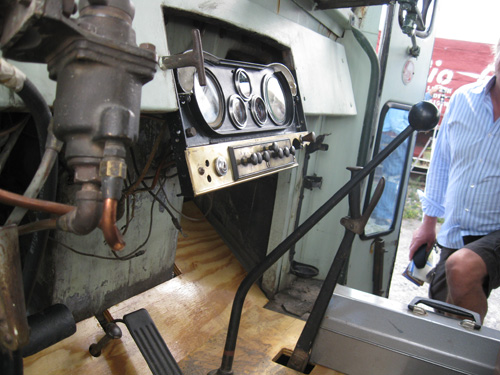

5) Wayne body separated from back and center truck

removed.

6) Bolster removed from center truck.

7) Removal of rear truck.

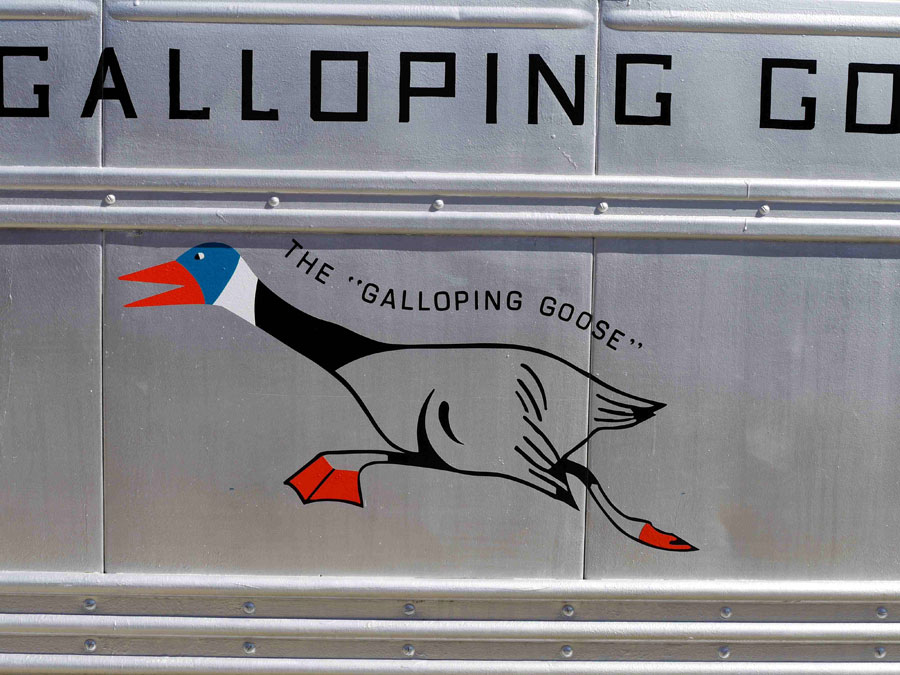

8) Removal of the interior siding begins

9) Removal of the outside metal sheeting

10) Siding removal continues. The box will be

completely rebuilt and then the siding reapplied.

11) The superstructure of the freight box has been

removed and next the floor was removed.

12) The deck construction is shown in this photo.

The base is made up of second-hand auto chassis U-channels filled with

wood. Note the bow in each channel. The wood was shaped not with a band

saw BUT WITH AN ADZE. The adze marks can be clearly seen. Next came 1 x

12s run at a 45 degree angle to the U-channels and finally tongue and

groove flooring running perpendicular to the u-channels. There were also

2 x 4s between the ends of each U-channel and a 2 x 4s were bolted to

the bottom ends of the U-channels

13) The freight box has now been completely cut down

to the base and the base primed. We will continue the project next

spring with the rebuilding of the freight box.

14) Construction of the new freight box began on

Saturday May 23, 2009. The wooden inserts are in the U-channels and work

begins on the wooden frame. Don Kellogg, Tom Hillhouse, Keith Koch and

Michael O'Connell.

15) The frame is complete and the first piece of

sub-flooring is attached (5/23/09). Michael O'Connell, Don Kellogg, Tom

Hillhouse, Karl Schaeffer and Keith Koch,

16) The sub-flooring is completed and addition of

the flooring is well underway (5/23/09). Keith Koch, Don Kellogg, Tom

Hillhouse and Don Paulson.

17) Flooring completed and wall construction begins

(6/3/09) Bill Pratt, Myron Matz, Michael O'Connnell and Tom Hillhouse

18) Two walls are up (6/05/09). Tom HillHouse,

Michael O'Connell and Stuart Harrah

19) Three walls are up (6/05/09). Tom Hillhouse,

Michael O'Connell and Stuart Harrah

20) Work continues on the motor (6/03/09). During

work week all the pistons were removed and the transmission was

successfully shifted through all gears. Don Kellogg and John Weiss.

21) 7/14/09. The four walls are up and the

original tin siding is being reattached to the walls. Karl Schaeffer

22) 7/21/09. The roof beams are now in place.

Keith Koch and Karl Schaeffer,

23) 7/28/09 Roof Slats are now up and the original

sheet metal siding is back on. Don Kellogg

24) August 11. Interior roof complete and metal

roof added.

25) August 18. Metal seams sealed with additional

metal sheeting. Stuart Harrah and DanTurner

26) October 1. Karl Schaeffer and Don Kellogg add

the awning over the windows. The freight box exterior is now completed

and sealed for the winter.

27) March 9, 2010. Goose #4 awaits spring 2010

restoration work.

28) May 19, 2010. The engine is removed for

rebuilding in Telluride.

29) May 27, 2010 (l) and June 28, 2010 (r). The

original interior wood is being reattached. The red or brown wood is

original siding that has been reattached and the white primed wood is

replacement pieces.

30) August 16th (L to R): Keith Koch and Stuart

Harrah installing the goose stove insulation; Karl Schaeffer, Tom

Hillhouse and Don Kellogg installing one of the drive axles. The

reinstalled Goose water tank used by the Motormen to refill the Goose

radiator.

\

\

31) September 15th (L to R):Sandblasting the Wayne

bus body; Michael O'Connell painting the sand blasted Wayne bus body

32) September 28th (L to R): Front Truck removed

for repair; Don Kellogg and Karl Schaeffer prepare to re-attach the

power truck

33) September 28th: Rod Bunyard (L) and Chris

Weiser (R) work on removal of the non-powered freight box truck.

34) October 5, 2010: (L) Chris Weiser and Don

Kellogg disassemble the front truck. (R) Tom Caldwell removes the

masking from the Goose bus body.

35) Oct 5, 2010: Goose No. 4, with its refurbished

power and rear trucks reinstalled and freshly painted, is ready for a

winter's slumber until spring 2011 when we will resume the restoration.

36) October 19, 2010: Chris Weiser has just

finished painting the seat pedestals, a tedious job that required

sanding, priming and repainting.

37) May 3, 2011. The rebuilt front truck is

reattached to Goose 4.

38) May 14, 2011. Chris Weiser, Bob Meyer and Karl

Schaeffer reinstalling the motor after rebuilding.

39) June 14, 2011. Dan Turner works on the stove

base.

40) June 14, 2011. Michael McConnel (L) works on

the brake rigging while Bob Meyer (R) puzzles over the clutch mechanism.

41) June 28, 2011. New radiator being admired by

Karl Schaeffer (L) and Bob Meyer (R).

42) July 11, 2011. The rebulit concession stand

takes shape.

43) July 26, 2011. Street car seats and Montgomery

Ward coal stove reinstalled in the freight box.

44) August 9, 2011. The re-caned seat backs were

installed in the freight box (left photo below) as well as the completed

concession stand. Chris Weiser's new bell was also installed (right

photo bvelow).

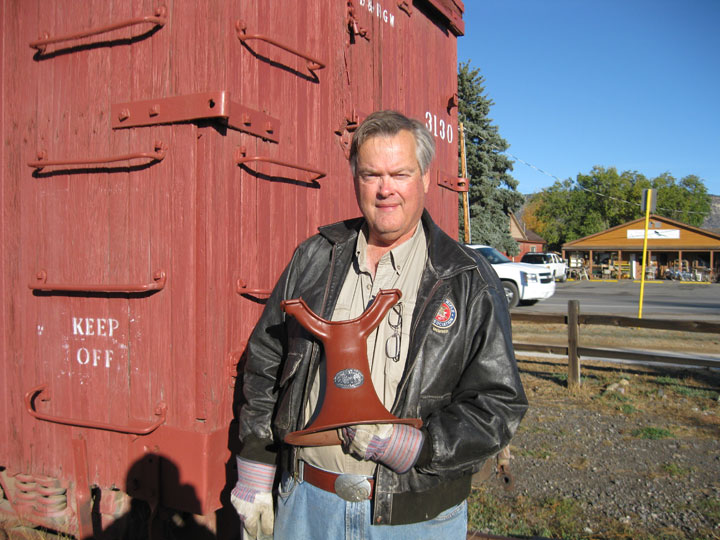

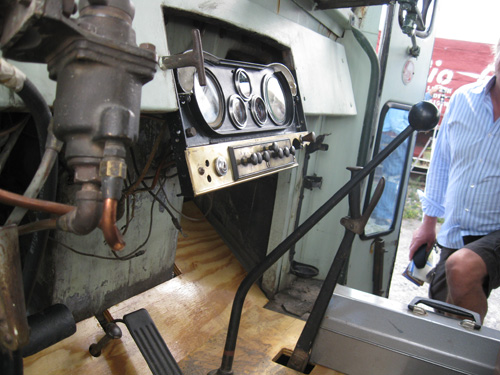

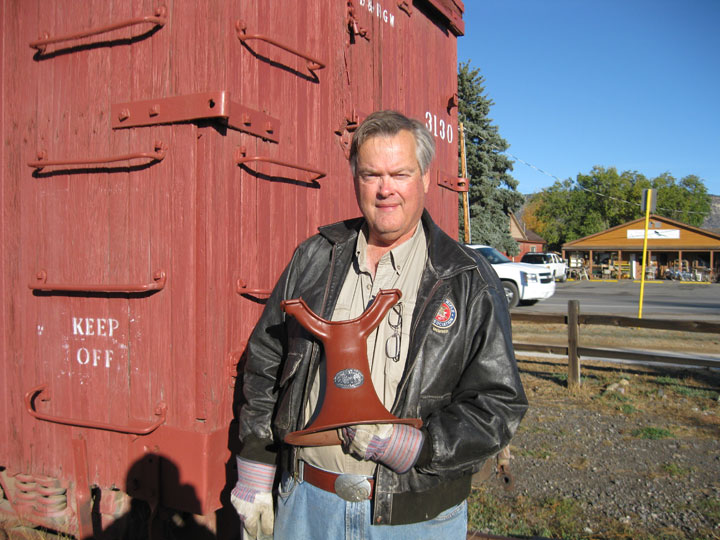

45) August 16, 2011. Bob Meyer's newly built dash

board and the first attempt in 58 years at starting the motor on Goose

No. 4

46) August 29, 20011. Goose No 4 makes about ten

round trips of 100 feet in each direction. Bob Meyer, Chris Weiser, Don

Paulson, Tom Hillhouse, Don Kellogg, Jim Pettengill and Karl Schaeffer

(All members of the Goose 4 restoration team) took turns running the

goose. Unfortunately, numerous other members of the team were not able

to be there. Click here

to see several videos of these runs: The photo below shows Karl

Schaeffer as Motorman.

47) September 3, 2011. The restored front

headlights and rear stoplights were installed.

48) September 13, 2011. The front end was painted,

the lights connected, the interior control panel painted and the snack

stand installed in the box. The third photo shows Greeley, CO resident

Tom Caldwell hard at work painting the pilot.

49) May 26, 2012. Karl Schaeffer, Tom Hillhouse, Bob

Meyer, Jim Pettengill and Don Kellogg applied some of the new lettering

to Goose No 4. Wow is all I can say!

All original

materials, text, and images Copyright 2011 by the Ridgway Railroad

Museum. All rights reserved. Unauthorized use or reproduction of any

materials, text and images without the express written permission of the

Ridgway Railroad Museum is strictly prohibited.

All rights to materials, text, and images attributed to other sources

are reserved to those sources. Unauthorized use or reproduction of any

these materials, text and images without the express written permission

of the owners is strictly prohibited.

\

\